News Articles

Excerpt from Fabshop Magazine

Third Dimension

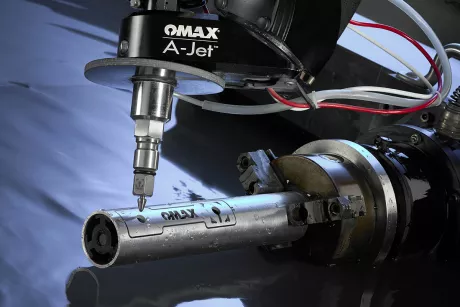

For a fabrication shop, versatility is key for taking on as many jobs as possible. The more often a shop can say “yes” to potential jobs, the more successful they will be. The easiest way to achieve greater versatility is by expanding capabilities. Shops that focus primarily on flat 2D work, for example, can add an articulated cutting head and/or rotary axis to their waterjet and have the opportunity to do 3D work without taking up additional valuable floor space.

The benefits of purchasing a waterjet with an articulated cutting head and/or a rotary axis, or adding them to an existing system, are numerous. Cutting with a waterjet allows for weld-ready parts without the need for secondary procedures, speeding up part production for pipe fitting applications. Using a waterjet to cut 3D shapes does not limit material capability like laser, plasma or traditional CNCs. Furthermore, the right waterjet software makes it easy to start cutting in 3D space.