LEARN ABOUT WATERJETS

LEARN ABOUT WATERJETS

WHAT INDUSTRIES USE WATERJET CUTTERS?

From jewelry making to aerospace, waterjets are involved in the production of many products you may not expect. Due to the versatility of cutting with abrasive and the ease-of-use of OMAX's software, OMAX brand waterjets are in a wide variety of industries. Below are just a few examples of industries where OMAX abrasive waterjets are thriving.

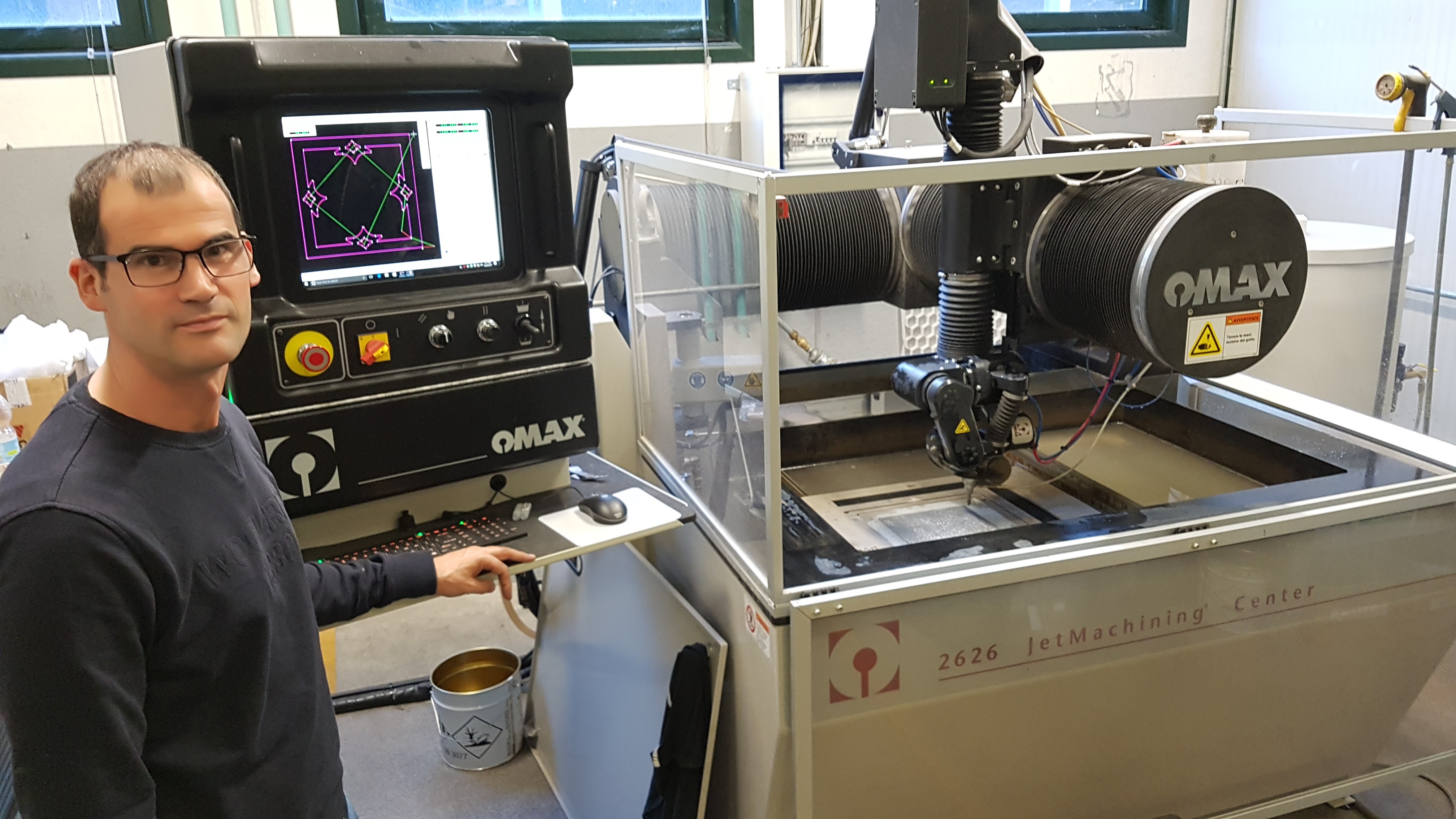

JOB SHOPS

Our easy-to-use abrasive waterjets add to your shop's capabilities to cut or machine a variety of materials at the speed and precision demanded by a range of industries.

Transportation

Waterjet cutting is an ideal solution for the transportation industry, especially where high-mix, low-volume production is the norm. Its ability to cut virtually any material without heat distortion makes it perfect for rapid prototyping and short-run manufacturing of custom components. With no need for tooling changes and minimal setup, waterjet enables fast iteration and precise fabrication of complex parts tailored to evolving design requirements.

STONE & TILE

Unparalleled precision and efficiency for cutting stone, tile, and marble, making them the ideal choice for your projects. OMAX waterjets are reliability and ability to cut different densities of materials easily make them versatile and dependable. With advanced water level control, OMAX waterjets unsure safe and clean working environment. Elevate your craftsmanship and achieve stunning, professional-grade stonework, tilework, and marble creations with OMAX waterjets. More Information

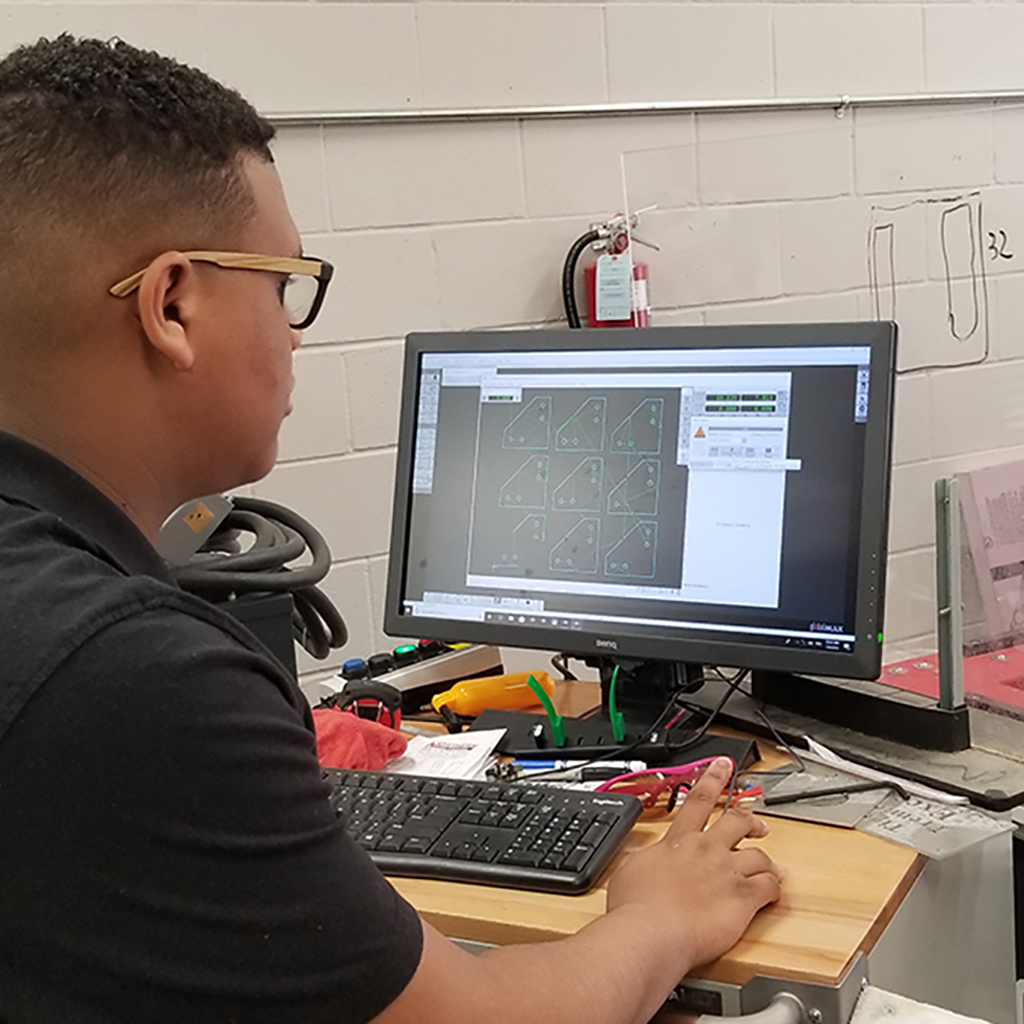

EDUCATION

Whether for training or research, our waterjets serve as learning tools for high school, trade school, college and university engineering and physics labs.

AEROSPACE

Abrasive waterjet has major advantages when Cutting carbon fiber. No need to change tooling. No special considerations or restrictions due to heat buildup. No melting. No hazardous fumes requiring costly air handling equipment. Any fiber-reinforced material, including Kevlar reinforced personnel armor, can be quickly and cleanly cut without the drawbacks that come with conventional machining.

FOOD PROCESSING EQUIPMENT

From the orange juice you drink at breakfast to the fish filet you had for dinner, abrasive waterjets were likely used to make the machines that process many of your favorite foods.

METAL SERVICE CENTER

The versatility of OMAX abrasive waterjets allow for cutting a wide variety of materials and thicknesses without any material distortion. Aluminum, steel, titanium: complete any order without tool changes. Modern waterjet systems are optimized to cut materials between ¼ inch up to 3 inches thick. Given enough time and consideration for taper, waterjets can cut as thick as you want. More Information

Government & Defense

OMAX abrasive waterjet cutting machines are particularly suited to the rigorous demands of defense manufacturing. These machines can process virtually any material used in the defense industry, including stainless steels, super alloys, Kevlar, composites, plastics, and ballistic glass. They provide the flexibility and versatility needed to keep pace with the constantly changing requirements of the defense sector.

ARTISTIC

OMAX waterjets give artists and designers the power to cut intricate patterns in metal, glass, and stone—without heat distortion. From jewelry to architectural installations, these systems deliver unmatched accuracy and material versatility. Whether you're a studio artist or a commercial fabricator, OMAX transforms raw materials into refined works of art with speed, control, and repeatability.

RELATED QUESTIONS

Every precision CNC machine shop contains multiple types of equipment. They often utilize mills, lathes, multi-axis machine centers, grinders, EDM machines, and precision hones. The goal of any machine shop is to add value to a product through the manufacturing process. Abrasive waterjet machines have a common place within a machine shop because they add value by eliminating non-value-add time and creating geometrics that are both common and/or not possible with traditional CNC machines. In part three of Complementary Machining, we’ll take a look at how waterjet works in unison with other manufacturing and fabrication methods as well as a waterjet’s return on a capital investment.

OMAX abrasive waterjets are the Swiss Army Knives of the machine tool world. Abrasive waterjet can: cut with a small kerf like a saw, cut external geometry for near net production, cut round parts like a lathe, cut square parts like a mill, cut complex parts like a wire EDM, and cut slots like a broach. This advanced versatility allows waterjet to be a large multi-tasker in your machine shop or to complement your other machine tools by balancing capacities

Free training courses are offered each month at the OMAX headquarters facility in Kent, Washington, located in close proximity to Seattle Tacoma airport. The Operator Training program is designed to lead you step-by-step through the process of making parts—from drawing to cutting. It gives you practical, hands-on experience in how to operate and maintain your equipment following best practices that have been tried and true in the lab and in the field. We provide you the information, practice, and resources to assist you in effectively operating and maintaining your equipment long after the training has ended.

As part of your OMAX purchase, you have total access to OMAX’s superior customer support. From software installation to cutting methods, our staff is trained to answer any questions you may have. Since OMAX customer support is on-site at our Kent, WA campus, they are trained on the newest technology and the most advanced machining practices pioneered by our engineers.

.jpg)