Tips & Tricks

Cutting Through the Complexity of Oil & Gas Manufacturing with OMAX

OMAX waterjets streamline oil & gas operations with precision cutting across corrosion‑resistant alloys and mixed materials—no HAZ, cleaner, and safer. Read

Five Reasons Why Waterjet Is Strengthening Defense Manufacturing

Waterjet technology delivers precision, adaptability, and safety—making it essential for modern defense manufacturing. Read

Why 2025 Is a Strategic Year to Buy Waterjet or Plasma Table

2025 offers manufacturers a prime opportunity to invest in waterjet or plasma cutting tables at reduced net cost—thanks to new tax advantages under the One Big Beautiful Bill Act (OBBBA) Read

Four Reasons To Always Use OMAX Genuine Parts

We’ve all done it: snapped up a generic, aftermarket replacement part or consumable in the quest to save a few dollars. But while the desire to cut costs is understandable, how much are we giving up in return for those short-term savings, and is it really worth it in the long run? Read

The Smart Choice: Buying American-Made Machine Tools

Choosing the right manufacturer is critical for ensuring high performance, durability, and long-term value when purchasing machine tools. In an increasingly globalized economy, many companies are tempted to outsource production to cut costs. That may not be the right option. Read

Abrasive Waterjet Machines: The Cutting Edge for Defense Manufacturing

Learn how abrasive waterjet cutting technology from OMAX provides efficient, flexible and profitable part processing for the defense industry. Read

Revolutionize Your Workflow: Add Waterjet Cutting

Enhance your shop’s capabilities with waterjet cutting technology. Discover how abrasive waterjets offer unparalleled versatility, allowing you to cut through diverse materials, reduce outsourcing costs, and minimize waste. Boost your profitability and efficiency by integrating waterjets into your workflow, regardless of your shop size. Explore OMAX's range of waterjet machines and transform your business today. Read

OMAX Order: The One-Stop Shop for Ordering OMAX Parts and Services

OMAX Order is OMAX’s innovative digital solution that puts guaranteed service and support in the palm of your hand with your abrasive waterjet cutting. This mobile app creates convenience, maintains efficiency and provides peace of mind for both your business and everyone on the shop floor. Read

The Significance of Scissor Plumbing in Waterjet Cutting

Scissor plumbing is a flexible and dynamic arrangement of high-pressure lines within a waterjet cutting system. It allows for movement along multiple axes without restricting water flow or abrasive. Read

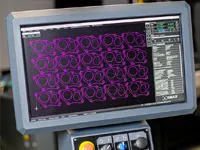

IntelliMAX Software Amplifies Waterjet Efficiency

Enhance the efficiency of waterjet cutting with the IntelliMAX Software Suite, for enhanced versatility, precision, and minimal waste. Discover how its functions optimize tool path, design and material usage for maximum efficiency. Read