The Future of OMAX and Waterjet Cutting

3D Cutting Preview

Our 3D cutting preview will allow for further design and machine-use review then ever before. Run simulations of your cut even before loading your material to ensure you are getting the best out of your waterjet. Scout potential cutting hazards, drafting errors, or unintentional lag.

Predictive Maintenance

OMAX's upgraded IntelliVISOR will be set up for more advanced monitoring and analytics. Using historical data, you’ll be able to program pump maintenance cycle reminders, mixing tube checks, and optimal usage. The upgraded IntelliVISOR interface will be available on your control console as well as remotely, making it possible for operators to monitor their OMAX waterjet from anywhere.

Industry 4.0

Industry 4.0 is the digital innovation of manufacturing and value creation processes. The advance in manufacturing includes the transfer of autonomy and autonomous decisions to cyber-physical systems and devices, leveraging information systems.

Augmented Reality

A technology that superimposes a computer-generated image on a user's view of the real world, thus providing a composite view.

Autonomous Robotics

A machine that operates with little or no external influence.

Big Data Analytics

The use of advanced analytic techniques against diverse data sets from different sources measuring in the terabytes.

System Integration

The practice of combining component sub-systems into a single operation to ensure continuity.

Advanced

Simulation

The method of using real world data to circumnavigate traditional trial and error testing by synthesized modeling.

Industry Internet

Interconnected machines, computers, and other devices networked together with automated industrial applications.

Cyber Security

The protection of networks from information disclosure, theft of or damage to their hardware, software, or electronic data.

Generative Design

When engineers input performance objectives into specific software, along with parameters such as materials, manufacturing methods, etc., then the software explores the permutations and generates design variations that meet user requirements.

Industrial Ecology

How materials and energy flow through a manufacturing industrial system.

Future Development

Future Development  Current Development

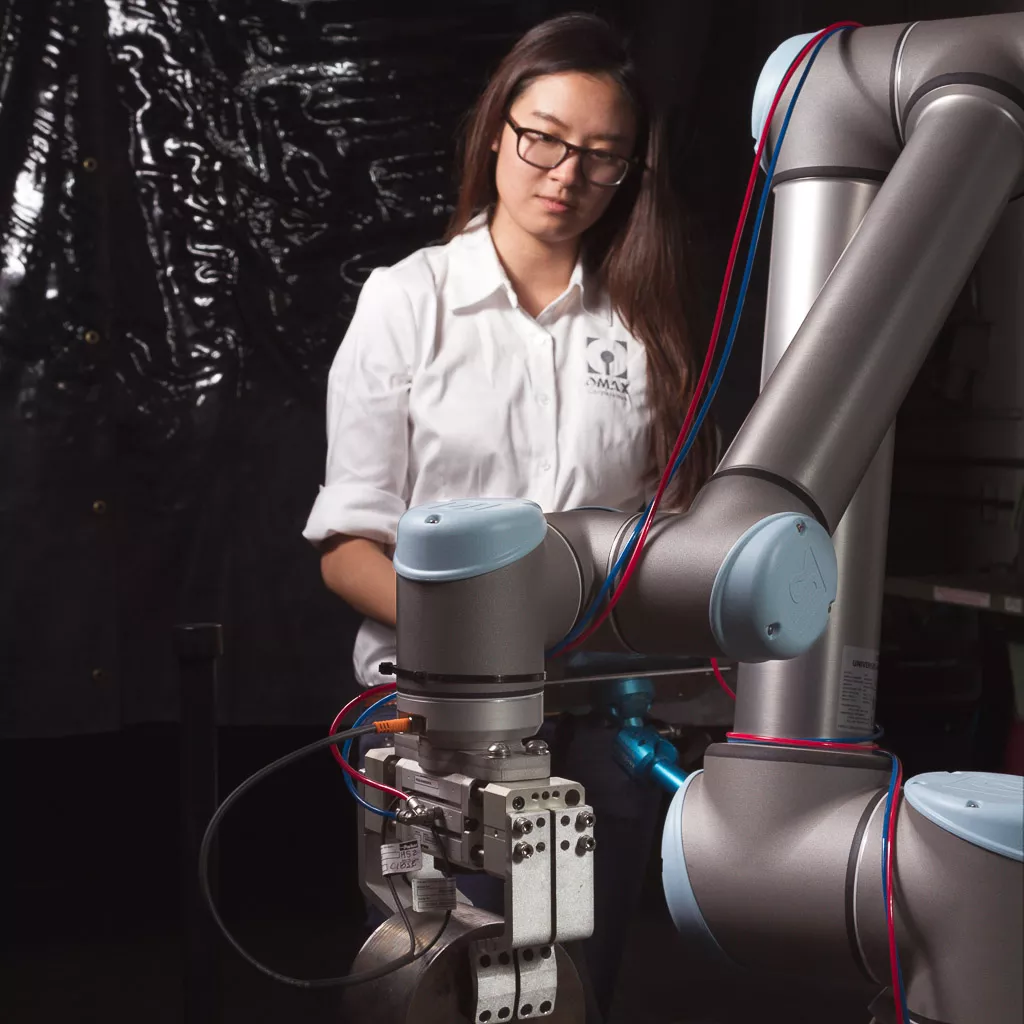

Current Development Robotics Integration

In the future, OMAX waterjets will have communication capabilities that command external devices. Robotic arms will be controlled centrally to load and unload parts as needed. Optical sensors will have the ability to locate and realign your waterjet nozzle accordingly. Automated feed systems could keep your waterjet loaded with garnet for days without additional attention.

Augmented Reality Training

OMAX Corp has always taken pride in our free operator training. We’ve always believed that a well-trained waterjet user is our best customer. In the future, we’ll be taking this to the next level with augmented reality service and training. From needing help with replacing a cutting head to a full pump rebuild, OMAX is finding way to provide you and your company with the best in cutting edge service and support.