News Articles

Excerpt from Canadian Fabrication and Welding

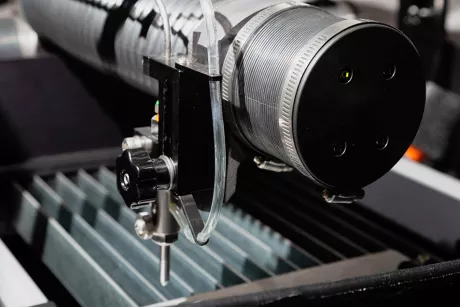

Optimizing your waterjet production

The best abrasive water jet cutting machines on the market are designed for rigorous machining. A combination of meticulous mechanics, rigid construction, and velocity control from the software ensures the highest degree of repeatable precision in the machined parts. However, even with all that built in, you can hone the machining process further by using your waterjet to the best of its abilities.

All waterjet users can benefit from reviewing best practices to improve their results with the technology. Many of these considerations may seem basic, but it’s the fundamentals that make or break the efficiency of waterjet machining – and it’s never been easier to find tips and tricks to optimize your waterjet.