Tips & Tricks

Precision Practices: Homing

OMAX waterjet machines are designed for high-precision machining. A combination of meticulous mechanics, rigid construction, and velocity control from the software ensures the highest degree of precision in the cut parts. Even with all that precision built in, you, as the operator, are able to hone that precision further by implementing a few fundamental practices. Thought it may seem rudimentary, homing your machine daily will help ensure optimum precision part machining. Homing allows for two contingencies: 1) the operator is able to reference known locations for secondary operations of an existing part. 2) If something out of the ordinary occurs (stalled motor, power outage, etc.) the operator can recover the machine’s position without having to scrap the part.

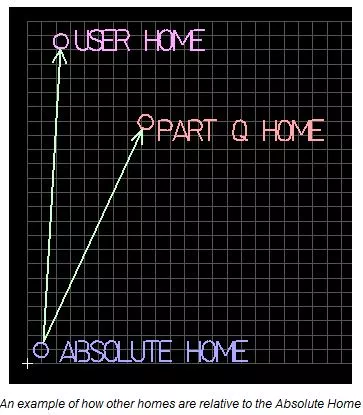

Homing an abrasive waterjet is the process of establishing a location on the machine’s cutting table where the nozzle can be moved in a repeatable way. An absolute home is usually established at the bottom left corner of the machine. This is a fixed point that determines all other points on your cutting table. Once the absolute home is established, then all other home locations (user home. part home, etc.) are defined as being a coordinate (distance) relative to the absolute home.

Some users only home their machine when the computer has been restarted. However, if the operator is not 100% sure the cutting head had not been bumped or realigned (with the power out to the motors when they were away), then they should re-home. This is for the operator’s peace of mind in confirming the integrity of the geometry. In some versions of OMAX’s IntelliMAX software (such as IntelliMAX Proto and Global) homing is required prior to commencing cutting operations.

With the exception of machines configured to force the operators to always run with the machine properly homed, it is perfectly normal and reasonable to operate a machine without ever homing; however, there is a little advantage to doing this. The operator gives up the ability to use soft limits as well as runs the risk that if something goes wrong during a cut (e.g. power goes out), recovering the part becomes difficult.

Establishing absolute home allows for the operator to cut in relation to the cutting table. For example, if an operator has a one-foot-square plate of aluminum that they are trying to cuts through at an exact location. When the operator knows the absolute home and fixtures the material to correspond with that point, they can program the cuts accordingly so that the finished piece can be replicated indefinably.

Most OMAX machines are equipped with either "limit switches" or "hard stops" that keep the machining nozzle from accidentally moving beyond the edge of the table. These limit switches are engaged when the nozzle reaches the limits of the table, and automatically stops movement before any damage can occur. If your machine is equipped with limit switches or hard stops, then the Auto Home feature can automatically set the home position by sensing the limit switches in the left bottom of the cutting table. For some older machines that do not have automatic homing, the Zero Absolute Home command sets your absolute home.

To auto home your abrasive waterjet:

- Move the machining head so that it is 5 to 20 in. (10 to 50 cm) from the lower left corner of the machine (near where the operator would stand when at the controller).

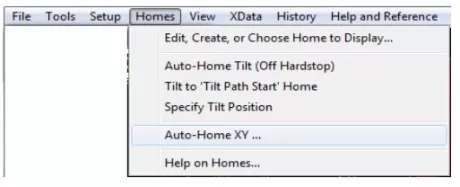

- From the Homes menu, choose Advanced, and then Auto Home.

- A warning will appear asking you to verify your Z axis is raised so that you don’t accidentally crash your cutting nozzle during the auto homing process. After reading the warning and verifying your Z axis is raised, click OK to start the automatic homing process.

Once homing is finished, MAKE now knows where the machine is positioned. Now, every home that was ever created is now restored and reliably usable again. These include your user homes, any homes you created, soft limits, and homes that are automatically tracked by the software including the “Path Start Home”. You can now reliably and precisely go to any of these positions.

For example: In the case of the “Path Start Home” this also means that you can recover back to any position of the last path you ran, which allows you to recover, even in the event that the power went out while in the middle of a part. (If the power went out when cutting a part, simply re-home the machine, choose “go to path start home”, and then “Go to spot on path”, and click right before the point in the path where the power went out, and then click “resume” to resume cutting.)

For more information on homing, you can consult your OMAX Interactive Reference (OIR) that is available with the premium IntelliMAX software package or check out ProtoMAX KnowledgeBase.