Tips & Tricks

Accessory Comparison: A-Jet vs. Tilt-A-Jet

As a powerful and fast way to handle virtually any material, abrasive waterjets are superior to laser, plasma and wire EDM for the overwhelming majority of applications. However, water behaves quite differently from those other cutting processes, and for many applications, the taper it produces would require additional machining or finishing. To address this, OMAX offers a complete range of accessories that automatically address taper – and we’ve taken that technology even further, to enable full 5 and 6-axis cutting.

Unlike a focused beam of high-intensity light, thin brass wire or carbide cutting tool, water’s liquid state can cause the kerf width to vary across the depth of the cut. Usually, this takes the form of a V-shaped taper, as the jet stream loses energy as it cuts and removed more material at the top of the cut than at the bottom. This form of taper occurs when cutting too fast, but cutting too slow can have the opposite effect, creating a reverse taper. Other forms of taper can also occur, such as barrel tapers in thick materials or irregular tapers caused by setup or calibration errors.

Taper can be reduced by optimizing processes – altering the cutting speed, stacking thin materials, placing the nozzle closer to the material, using high-quality abrasive – but eliminating it entirely requires a tilting head. By positioning the nozzle at a precise angle relative to the material, the natural taper can be offset to produce a perfectly square, taper-free edge for parts. This functionality alone means a tilting cutting head can eliminate a significant amount of post-waterjet machining for high-precision work.

However, much more is possible with two accessories offered by OMAX – A-Jet and Tilt-A-Jet - which provide two different levels of control over the process:

A-Jet

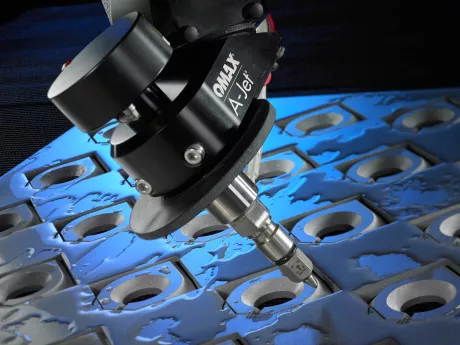

For more sophisticated control and a far greater range of part-production capabilities, OMAX users can also opt for the A-Jet, an accessory that goes far beyond automatic taper compensation. Featuring 60° of movement with ±0.09° positioning accuracy, the A-Jet’s true 5-axis cutting makes countersinks, weld-ready edges, and more easy to achieve. Even complex 3D parts such as propellers become possible with this technology.

Tilt-A-Jet

The Tilt-A-Jet is in a class of it's own and it only available with OMAX. A worry-free method for simple, easy taper correction, the Tilt-A-Jet gives operators the ability to achieve taper-free part edges with a single click in IntelliMAX on nearly all full-size OMAX machine models. No guesswork or programming expertise is required, as the system automatically adjusts at thousands of points per inch along the cutting path. But the Tilt-A-Jet does much more than taper correction. Precise control over the angle (±9°) means that interlocking pieces, dovetail fitting and taper-free lead-ins all help to expand the capability of a waterjet, while the ability to change angles quickly allows for faster cutting speeds.

OMAX’s innovations don’t stop with the cutting heads, however. The addition of the Rotary Axis, a submersible rotary head that turns cylindrical parts, makes true 6-axis cutting possible for complex 3D shapes in tubes, pipes and bar stock. Contact your OMAX sales representative to learn more about these options today.