Tank Enhancements

Continuous Feed Hopper CFH600

The innovative Continuous Feed Hopper improves your production times by automatic garnet delivery to the abrasive waterjet nozzle. Utilizing pneumatic pressure to transport garnet from the large capacity 600lb (272 kg) hopper pot to the cutting head hopper, the Continuous Feed Hopper helps to eliminate unplanned downtime with the ability to fill the hopper while in use.

The Continuous Feed Hopper is designed to maximize production while simplifying operations. Quality engineering has resulted in a system that is easy to use and maintain.

Available on these machines:

OptiMAX 60X, OptiMAX 80X Series, OMAX 2626, OMAX 2652, OMAX 5555, OMAX 55100, OMAX 60120, OMAX 80X, OMAX 120X Series, OMAX 160X, MAXIEM 1515X, MAXIEM 1530X, MAXIEM 2030X, MAXIEM 2040X, MAXIEM 2060X, MAXIEM 2080X, MAXIEM 3060X, GlobalMAX 1508, GlobalMAX 1530, GlobalMAX 2040

Contact Sales

Features

• Designed for sustainability with recyclable plastic hopper and modular steel frame

• A removable screen provides pre-filtration that reduces downtime due to abrasive contamination

• The large 600 lb (272 kg) hopper pot size provides hours of uninterrupted cutting

• The open design allows for improved maintenance and troubleshooting accessibility

• A low-level indicator light provides instant visual notification to facilitate refilling of the hopper pot

• The integrated lid and screen allows users to fill the hopper pot while in use

Bulk Abrasive Delivery System

Available in multiple sizes, the Bulk Abrasive Delivery System uses pneumatic pressure to automatically transport garnet from an external bulk abrasive hopper to the cutting head hopper. The Bulk Abrasive Delivery System can extend your cutting times from under an hour to over a day.

Available on these machines:

GlobalMAX 1508, GlobalMAX 1530, GlobalMAX 2040, MAXIEM 1515X, MAXIEM 1530X, MAXIEM 2030X, MAXIEM 2040X, MAXIEM 2060X, MAXIEM 2080X, MAXIEM 3060X, OMAX 2626, OMAX 2652, OMAX 5555, OMAX 55100, OMAX 120X Series, OMAX 160X, OptiMAX 60X, OptiMAX 80X Series

Contact Sales

Features

- Available in 100lbs., 2200 lbs. Systems

- Heavy-duty steel construction

- Automatically feeds the garnet hopper located next to the cutting head

- Integrates with OMAX IntelliVISOR System Monitoring Package

- Can be located 20 feet (6 m) from the machine

Large Solid Removal System

The PLC-controlled Large Solids Removal System (LSRS) provides precise control over evacuation rate, zone selection, and duration for efficient removal of spent abrasive from a large-bed waterjet catcher tank. The LSRS gives the user operational flexibility by allowing placement of the LSRS up to 100 feet (over 30 meters) away from the JetMachining Center.

Available on these machines:

OMAX 120X Series, OMAX 160X

Contact Sales

Features

- Standard Hopper can collect 2,200 lb (1,000 kg) of abrasive in industry standard bag size

- Skid & Hopper Unit can be located remotely, up to 100 ft (30.5 m) for optimum facility placement

- 1.5 HP diaphragm pumps provides strong suction power

- Abrasive removal rates up to 30 lb/min (13.6 kg/min)

- cUL-US compliant

Variable Speed Solid Removal System

The Variable Speed Solids Removal System (VS-SRS) gives the operator the ability to program flow rate and direction. The controller's programmability provides greater garnet removal than comparable fixed speed units. An optimized fluid return trough increases settling time and minimizes abrasive volume returning to the tank.

Available on these machines:

MAXIEM 1515X, MAXIEM 1530X, MAXIEM 2030X, MAXIEM 2040X, MAXIEM 2060X, MAXIEM 2080X, MAXIEM 3060X, OMAX 2626, OMAX 2652, OMAX 5555, OMAX 55100, OMAX 120X Series, OMAX 160X, OMAX MicroMAX, OptiMAX 60X, OptiMAX 80X Series

Contact Sales

Features

- Garnet removal rate as high as 5.6 lbs/min

- Productively removes both large and fine particles

- 3/4-yard hopper that includes liner for ease of removing garnet from hopper

- Optimized fluid return trough minimizes abrasive volume returning to the tank

- UL, CE and CSA compliant

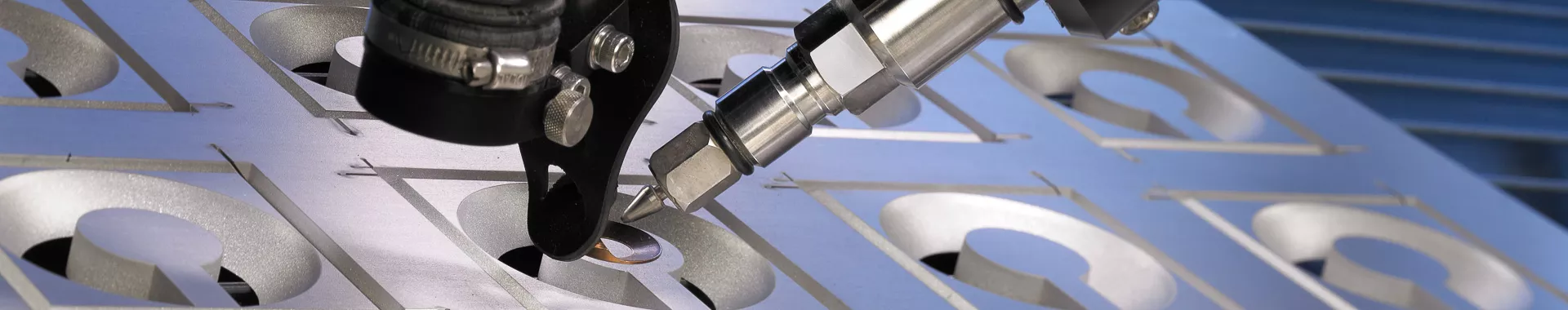

Scissor-Style Plumbing

OMAX Scissor-Style Plumbing replaces the standard whip on the MAXIEM line and OMAX 2626. Scissor-Style Plumping increases flow between the pump and cutting head with a larger interior diameter 3/8 in (9.5 mm) diameter rather than the 1/4 (6.3 mm) in interior diameter of the whip.)

Available on these machines:

OMAX 2626

Features

- Only requires 10-foot ceiling height

- Increased water flow at the nozzle

- The rigid plumping is easier to maintain

- Swivels allow for compact machine tool operation

- Required for the A-Jet and Dual Pump configurations

Water Level Control

The OMAX Rapid Water Level Control is an easy-to-use, in tank pneumatic system that enables you to quickly raise and lower the water level of your catcher tank for underwater cutting. System control is conveniently located near the controller side of the waterjet for easy access.

Available on these machines:

MAXIEM 1515X, MAXIEM 1530X, MAXIEM 2030X, MAXIEM 2040X, MAXIEM 2060X, MAXIEM 2080X, MAXIEM 3060X

Features

- Reduced garnet and water splash

- Lower noise level to approximately 76 db. when cutting under water

- Minimizes frosting on finished parts

- Control placed on controller for easy use

- Helps maintain constant water level in the tank

Machine Status Indicator

Decrease operator observation and increase productivity with the machine status indicator lights for OptiMAX. Utilizing industry wide known-colored lights, operators can safely monitor the abrasive waterjet from a distance while also operating other equipment or completing other tasks while watching 4 active lights on the stack.

Available on these machines:

OptiMAX 60X, OptiMAX 80X Series

Features

- White Light: waterjet is idle and ready to operate with no faults

- Green = normal operation, indicating a waterjet action is taking place, such as performing a cut, move, or test, and no faults or abnormal conditions are present

- Amber = an abnormal condition, but the waterjet can continue performing cutting and moving operations

- Red = a fault condition, and the waterjet will be unable to perform any cutting operations

Under Bridge Lighting

Improve productivity and safety with under bridge lighting for OptiMAX. Direct illumination of the cutting surface allows for the operator to clearly see the nozzle location, with two LED light banks to aid in cut set up, visibility, and project completion.

Available on these machines:

OptiMAX 60X, OptiMAX 80X Series, MAXIEM 1515X, MAXIEM 1530X, MAXIEM 2030X, MAXIEM 2040X, MAXIEM 2060X, MAXIEM 2080X, MAXIEM 3060X

Features

- Upon turning on the waterjet the lights will illuminate under the bridge

- Increase operator safety with more light to see the work piece

- More uptime and visibility of cutting path and parts

OptiMAX Bridge Pendant

The OptiMAX® Bridge Pendant allows the waterjet operator to move the Cutting Head and the Bridge along X, Z and Y Axis, dial in the cutting head to the work piece, or perform dry runs to test drawings or material fixturing.

Available on these machines:

OptiMAX 60X, OptiMAX 80X Series

Contact Sales

Features

- Handheld pendant that is easy for operators to hold and work on the material.

- Rotator dial to move the Cutting Head and Bridge along the X, Z and Y Axis.

- Ability to run a dry run on path to make sure the material and the geometry are set up correctly.

- Mounted on the bridge upright for quick grab and access to the whole cutting envelope with a 16ft long cord (5 meters).

- Integrated with the OMAX IntelliMAX® MAKE software, with clear signals to tell the operator if the main controller or the pendant is active and in control.