Tips & Tricks

Using Sacrificial Material

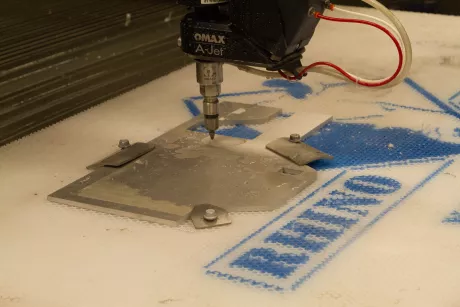

If you are accustomed to cutting aluminum or steel of 1/4 inch (or thicker) flat stock, you probably haven’t needed to use a sacrificial material. However, when cutting thin, brittle or tubular material, a sacrificial piece may make all the difference in quality waterjet machining.

Why should you cut on sacrificial material?

The three main reasons to use backing sacrificial material are to stabilize thin materials, to reinforce brittle materials, or reduce frosting. There is also another type of sacrificial material used for cutting tubes on a rotary for entirely different reasons.

It is important to note that when using a material as a backing, that the sacrificial material needs to be softer than the work material. This is so that the waterjet’s jetstream pierces without much resistance.

When cutting very thin materials (for example 0.04” aluminum) the initial piercing of the waterjet may create enough force to cause distortion. By securing the thin material to the sacrificial backing, you provide additional rigidity to the work material while ensuring an accurate cut.

When water jetting brittle stock (glass, quartz, some laminates) there is a slight possibility of chipping at the edge. To resolve this issue, you’ll want to add a backing material to add rigidity to the work material. The sacrificial material keeps the jetstream focused beyond the work material and into the backing, keeping your cut clean.

Frosting is the effect of stray particles abrading the surface of the material being cut. It typically occurs right at the edge of the cut, or in a circular pattern around a pierce. Using a backing board as sacrificial material will greatly reduce potential frosting.

Unlike the previous mentioned reasons, cutting a pipe or tube on a rotary needs a sacrificial material so that you don’t cut through the other side. In this case you want your sacrificial material to be harder than the work material so it absorbs the power of the jet.

What types of sacrificial material is out there?

For most backing types of sacrificial material, you can typically get away with scraps that may be laying around your shop. Drywall is ideal for backing thin metals and glass. Another cheap option for small scale cutting is linoleum tiles. You don't want to use wood as a backing surface as it may swell with the water and create an uneven surface to cut on. Ultimately, you are looking for something rigid but softer than the work material.

In some cases, you may be able to use waterjet table inserts like Jet-BRICK or Rhino Board. Both products are rigid and long lasting making them ideal for multiple uses. It is also possible to screw additional fixturing directly into these products.

For rotary cutting on pipes and tubes, you’ll need to find something harder (rather than softer) than the cutting material. Often this is done with a thick carbon rod inserted into the middle of the pipe. Carbon is brittle but strong again the garnet cutting media.