Tips & Tricks

Waterjet Collision Prevention

When collisions happen, they usually come about because of one or two reasons:

- A slug freed from the material has been pushed up from below, creating an obstacle on the cutting surface

- The material is not perfectly level

Fortunately, there are a few simple tricks to help prevent collisions and unnecessary downtime.

Slugs that create problems are small enough to be light and movable while being too large to fall through the slat bed. One very simple way to help mitigate this issue is to run the “Check for Problems” command during programing and just before cutting. “Check for Problems” will check your tool path to see if it can identify any areas where the nozzle may collide with pieces of material that have already been machined. For example, if you cut a hole in your piece and then move the nozzle across the hole, this will be identified as a collision area, because the round piece of material may tilt up and strike the nozzle.

The “Check for Problems” button is available after you use the “Generate Tool Path” command to create a tool path. This button is also available underneath the Preview window in the “Change Path Setup” command in MAKE.

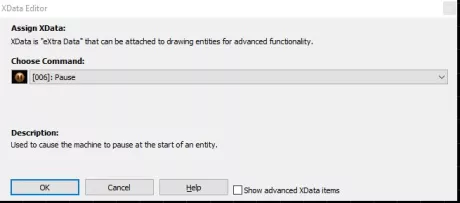

An alternative way to mitigate possible slug collisions is to use XData and add a “Pause.” To add a “Pause” into your cut path using XData:

- Select the entity that you would like the cut path to pause.

- Click XData at the top of the screen and click “Edit XData for selected…”

- From here, you will have a large list of possibilities from which to choose. To pause your machine while in the middle of a cut, you’ll want to select “[006]: Pause.” Now your machine will pause just before the selected entity.

Note: You may want to draw a traverse path well out of the way of the cut path so that you can remove the slug without bumping into the cutting nozzle.

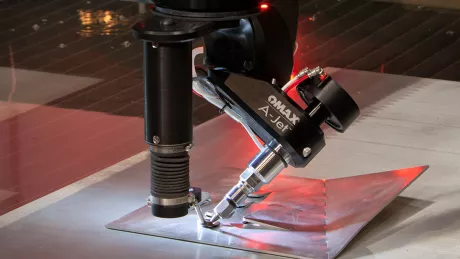

It’s not always easy tell if your working material is perfectly even – variations of hundredths of an inch on a large plate of aluminum are hard to see with the naked eye. However, if you set your original offset at a low point on the plate and the plate isn’t even, you may find yourself with a cracked mixing tube. If you experience uneven material, it might be a good idea to add a Collision Sensing Terrain Follower to your OMAX waterjet.

The Collision Sensing Terrain Follower is an essential tool for working with uneven surfaces. In addition to maintaining precise standoff, the Collision Sensing Terrain Follower also detects potential collisions and pauses the machine to avoid hardware damage.

Learn more about the Collision Sensing Terrain Follower here.