Tips & Tricks

The Importance of Slats

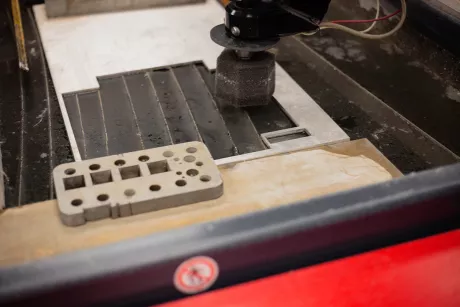

Slats are the stainless steel plates that support the material being machined in an OMAX abrasive waterjet. They are the best, most universal solution for supporting material. The standard slats that come with your OMAX waterjet can easily handle everything from metal plate and glass to stone and plastic, as well as nearly any other material.

Waterjet users tend to place parts to be cut on one part of the table. For example, you may routinely cut in the bottom left corner of the table because it is nearest to the waterjet’s controls. As a result, slats will develop uneven wear over time, which may cause your material to rock on the slats during machining. This rocking will dramatically reduce the precision of your OMAX waterjet. To ensure accurate cutting, it is important to maintain your slat bed.

Rotating the Slats

The slats that support the material in your abrasive waterjet erode over time and will eventually need to be replaced. You can greatly extend the working life of your removable slats by periodically rotating them. Any weakened and worn slats should be replaced.

The slats can be flipped horizontally or vertically; you may also move them to a different area of the table entirely. Create a schedule to inspect and rotate the slats at least once a month. When replacing a defective slat, inspect the slat holder for excessive wear. Worn slat holders should also be replaced. New sets of galvanized steel slats can be ordered directly from OMAX.

In addition, if you have a precision head such as a Tilt-A-Jet or A-Jet that requires calibration, make sure that you calibrate on a level surface, as the process will not work correctly on worn slats.

Using Drop Slats

While we’re discussing slats, have you ever considered using drop slats? Drop slats have a section that is several inches lower than the standard slats. This allows operators to more easily cut one side of a three-dimensional piece or cut thick materials underwater. By using the drop slats, a waterjet can cut regardless of the machine’s z-height.

Learn more and download the DXF file, which includes a simple drop slat drawing. The LAYOUT file can be adjusted to fit your own machine’s specifications.