OMAX Waterjet's: A Metal Service Center's Secret Weapon

OMAX is the right choice for metal service centers because of its industry-leading precision, reliability, and comprehensive support network. Waterjet cutting is the perfect solution for metal service centers looking to enhance their capabilities and efficiency.

NO HAZ - OMAX abrasive water revolutionizes the cutting process by eliminating the Heat-Affected Zone (HAZ). Unlike traditional thermal cutting methods, OMAX waterjets utilize a high-pressure stream mixed with abrasive particles to cut through materials without introducing heat. This cold-cutting technology preserves the original properties of materials, making it particularly advantageous for non-ferrous metals and specialty alloys, which are highly sensitive to heat and prone to distortion or degradation.

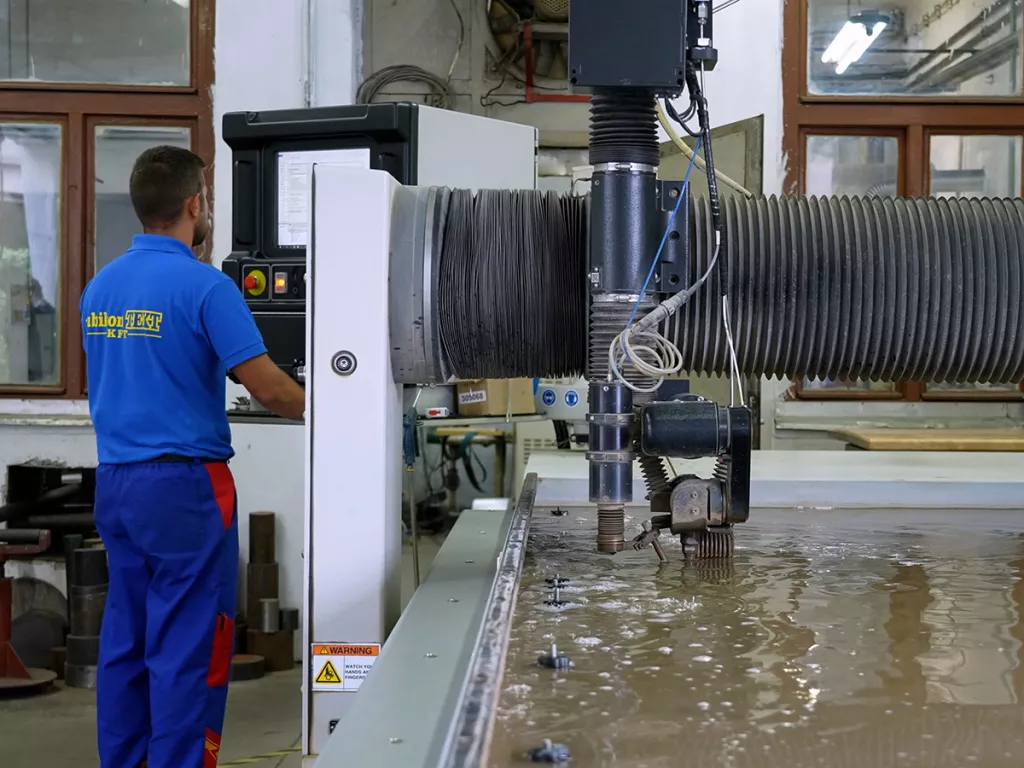

Cut Any Metal - OMAX waterjets provide exceptional precision and efficiency when cutting non-ferrous metals and specialty alloys. Whether dealing with aluminum, brass, titanium, or other advanced alloys, OMAX systems, are able to cut any metal with a few clicks of a button. The versatility and reliability make OMAX waterjets an ideal choice for Metal Service Centers handling diverse material requirements.

Faster Cut Time - OMAX waterjets also excel in cut speed and uptime. Their advanced direct-drive pump technology, as seen in the OMAX MAXIEM series, ensures consistent performance and reduced maintenance needs. The innovative software integrated into OMAX systems, such as the IntelliMAX control, optimizes cutting paths for maximum precision and speed.

OMAX Delivers a Reliable, User-friendly System Tailored for Long-term Profitability and Operational Excellence.

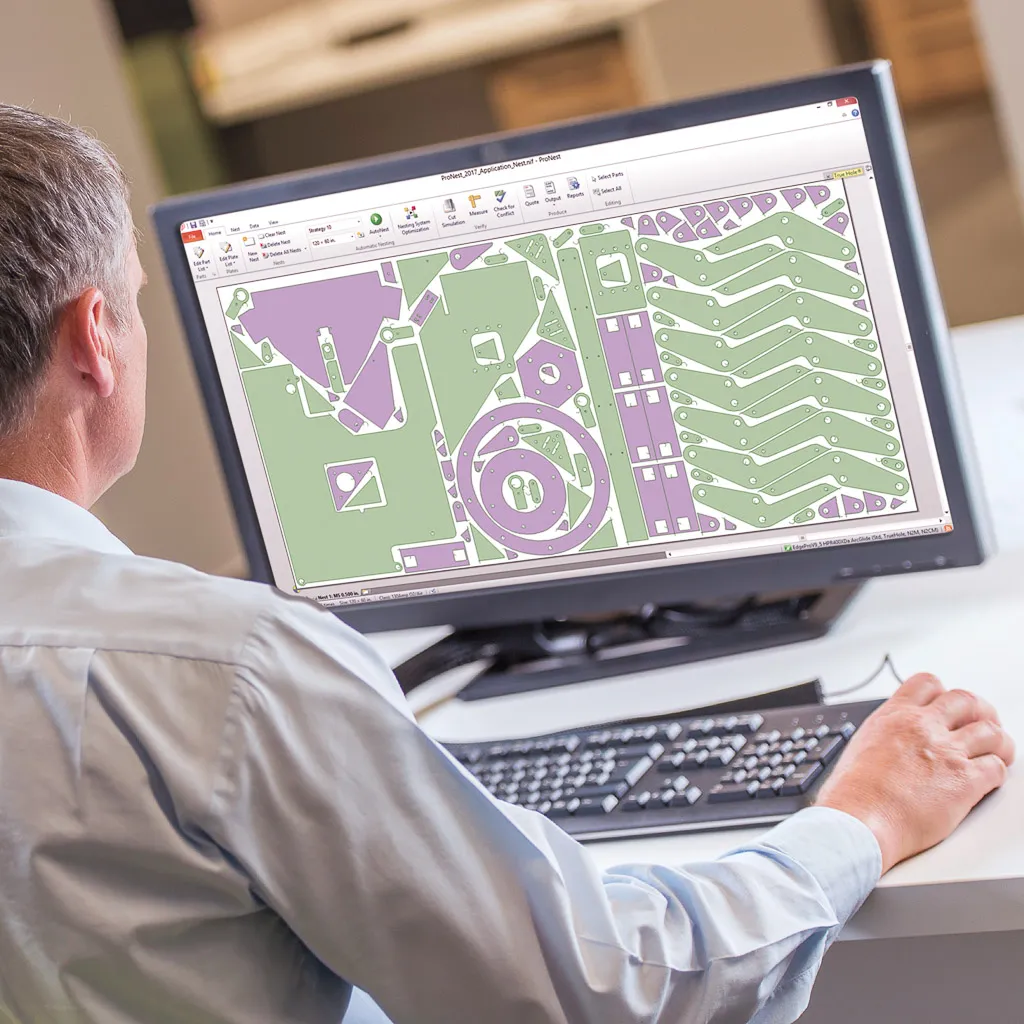

- ProNest uses advanced nesting algorithms to arrange your parts quickly and efficiently for maximum material utilization. This optional software is designed to work directly alongside IntelliMAX.

- A safe waterjet increases productivity, and our ergonomic, large platform table is designed for safe loading/unloading with any lift equipment process from all sides

- IntelliMAX software makes operating the waterjet simple while providing maximum precision, high speed, optimized precision, and minimizing waste.

- In-person training, virtual training courses and FREE lifetime support to ensure productivity, safety, and profitability.

- OMAX helps you boost efficiency and minimize downtime with its Service Program and IntelliVISOR monitoring software, which alerts you when routine maintenance is needed.

Waterjet uses a high-pressure stream of water, often combined with abrasive materials, to slice through various metals with unmatched precision. Unlike traditional cutting methods, waterjet cutting generates no heat, preserving the integrity and quality of the metal. This makes the cutting tool ideal for producing intricate, high-quality parts that meet your customers' exacting standards.

OMAX offers a full spectrum of waterjet machine tools, including the OptiMAX, OMAX, MAXIEM, GlobalMAX, and ProtoMAX brands, ensuring a solution for every need. The company designs, manufactures, assembles, and tests all components as a complete system, guaranteeing optimum performance. OMAX's advanced waterjet systems are known for their ease of use, thanks to intuitive software and features like the Tilt-A-Jet for taper-free cutting.