Tips & Tricks

Precision Practices: Tool Offset

OMAX waterjet machines are designed for high-precision machining. A combination of meticulous mechanics, rigid construction, and velocity control from the software ensures the highest degree of precision in the parts. Even with all that precision built in, you, as the operator, are able to hone that precision further by implementing a few fundamental practices. Last month Precision Practices looked at lead-ins and outs and how you place them in LAYOUT to mitigate blemishes while cutting. This month we will take a look at tool offset.

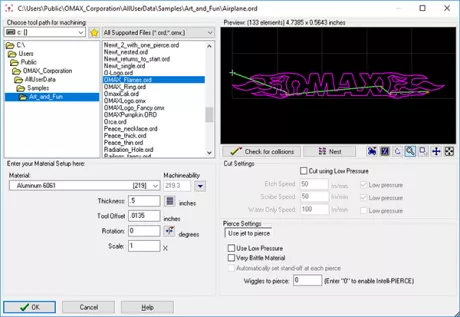

In MAKE, after loading the file you created in LAYOUT, you can choose from preferences such as material, thickness, and tool offset.

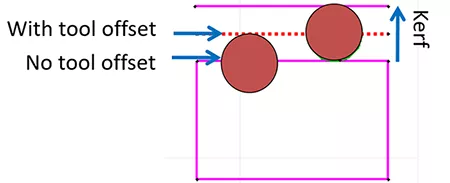

The material and thickness will be determined by what you are cutting. Tool offset is the distance that the tool has shifted away from the cut path to compensate for the diameter of the jetstream (kerf). Note that the offset itself is usually half the width of the kerf.

When you designed your project in LAYOUT, you programmed a cut path where the waterjet would pierce and cut your material. Tool offset is the distance the tool is shifted away from the cut path to compensate for the diameter of the jet stream (kerf). Without your offset properly designated in MAKE, your jet stream may cut into your finished product or leave excess material, creating a part that is out of tolerance.

Measuring kerf and adjusting your offset to compensate for mixing tube deformation is a whole other topic that we will look at in next month’s Precision Practices blog. If you are looking for more information on this right now, check out your OMAX Interactive Reference (OIR) or you can read about measuring kerf here.

MAKE may display messages stating that the offset is too large or too small. If an offset is too large, you are in danger of causing cut damage to your part. Offsets that are too large become an issue when there are tight corners and fine details. It is fine to use smaller offsets in MAKE. The warning message will display because normally such a small offset would not be used--unless the kerf is also very small, it will remove more material than normal, and the part will be out of tolerance.

Here are a few tips for working with your offset:

- Use the preview tools to preview the offset after you have generated your tool path. When you “Post” your design from LAYOUT, you will be given a “Preview of…” box. Here you can preview and adjust a tool offset. This is not necessarily the tool offset that will be used in MAKE, but it gives you the ability to experiment with offsets without altering your original design. If your part previews fine with a given offset, it will cut fine in MAKE using that size offset or smaller. Try experimenting with offsets just slightly larger than you expect to run in MAKE in order to ensure it will run nicely regardless of the machine setup.

- Tiny entities at inside corners often cause gouging as the offset follows the programmed cut path entities regardless of proximity to other entities. Some amount of automatic processing may occur to improve the results. To avoid this problem, erase and redraw any such geometry.

- Arcs smaller than a tool offset amount will be automatically removed by the software in some cases. The best way to avoid such problems is to avoid using internal arcs that have a radius equal to or smaller than the tool offset. A way around this is to use a radius of 0 on inside corners and the program will automatically use the offset of the path as the radius for the part.

In MAKE there are a few applications where offset can be ignored. The “slit” function under quality cuts acts the same as any other cut; it cuts directly on the cut path, ignoring offset. The “cut-off saw” function also ignores offsets since the intent is to saw through material without consideration to precision tolerances. Offset is also ignored while etching and scribing.

For more information on tool offset, you can consult your OMAX Interactive Reference (OIR) that is available with the premium IntelliMAX software package or check out the ProtoMAX KnowledgeBase.