Multi-Axis Cutting

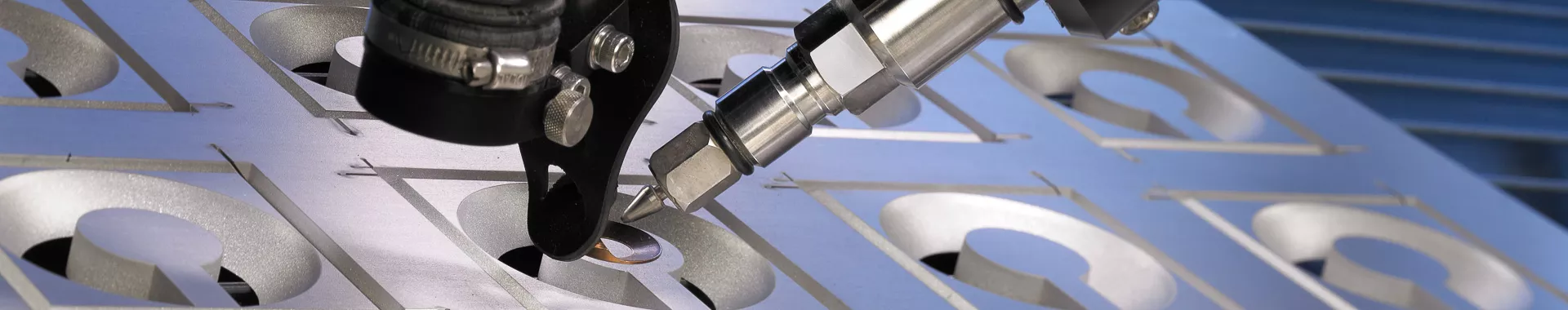

VersaJET

The VersaJET is a completely software-controlled 5 Axis cutting head that greatly expand the versatility of your abrasive waterjet. VersaJET has a cutting range of 0 to 60 degrees for cutting beveled edges, angled sides, countersinks, and complex 3D shapes. The cutting head virtually eliminates taper on finished parts with automatic taper compensation. With its inherent high level of positioning accuracy, the VersaJET can cut parts that don’t require secondary finishing, significantly reducing part production time.

Available on these machines:

OptiMAX 60X, OptiMAX 80X Series, MAXIEM 1515X, MAXIEM 1530X, MAXIEM 2030X, MAXIEM 2040X, MAXIEM 2060X, MAXIEM 2080X, MAXIEM 3060X

Contact Sales

Features

- Completely controlled with OMAX IntelliMAX Software

- Supplied with a MAXJET 5i Nozzle, which includes an OMAX High Angle Fusible Mixing Tube

- Fixed focal point design, where the XYZ axes do not need to move as the head tilts

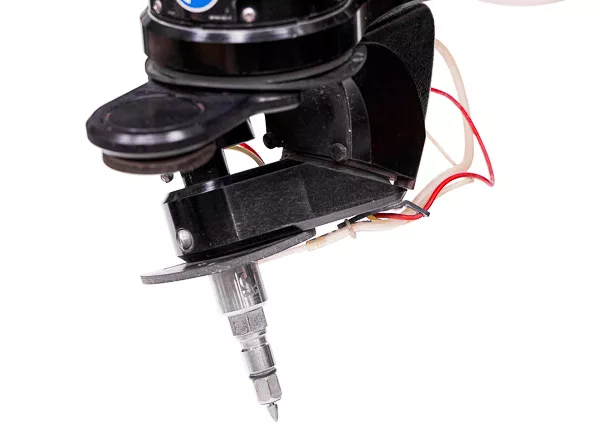

TiltAJet

The TiltAJet represents OMAX innovation in the continuing search for more accurate abrasive waterjet machining. TiltAJet can position the nozzle at an angle calculated by the software to exactly offset the taper from the abrasivejet. Taper doesn't disappear--it just gets moved to the scrap part of the material, leaving your part with exactly square edges.

Available on these machines:

OMAX 2626, OMAX 2652, OMAX 5555, OMAX 55100, OMAX 120X Series, OMAX 160X, OptiMAX 60X, OptiMAX 80X Series

Contact Sales

Features

- Automatic re-squaring feature ensures nozzle is square to the table

- Faster cutting of high precision taper free parts with no need to slow down to eliminate taper

- Servo-controlled programmable precision Z-axis with 6” of travel

- Faster cutting due to “tilt forward” capability

- Programmable manual tilt up to ±9° for the maximum tilt angle

AJet

The AJet is a completely software-controlled multi-axis cutting head that greatly expands the versatility of the OMAX JetMachining Center. With a cutting range from 0° to 60°, the AJet can easily cut beveled edges, angled sides, countersinks as well as complex 3D shapes. With its inherent high level of positioning accuracy, the AJet can cut parts that require no secondary finishing, significantly reducing part production time.

Available on these machines:

OMAX 2652, OMAX 5555, OMAX 55100, OMAX 120X Series, OMAX 160X

Contact Sales

Features

- Fully automatic taper compensation to minimize taper on finished parts

- Three modes of taper compensation

- Supplied with a MAXJET 5i Nozzle, which includes an OMAX High Angle Fusible Mixing Tube

- Designed for high flow/high power abrasive waterjet applications with multiple pumps by using large diameter tubing with minimal pressure loss

- Features a fixed focal point design, where the XYZ axes do not need to move as the head tilts

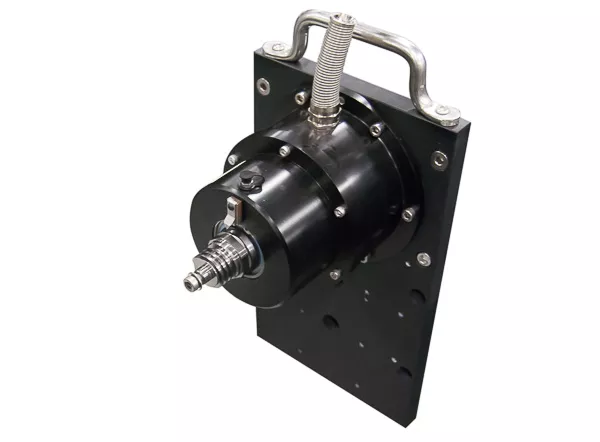

Rotary Axis

The Rotary Axis is a submersible rotary head that allows the abrasive waterjet to cut up to 6-axis paths to create complex 3D shapes in tube, pipe, and bar stock. Advanced software features in the IntelliMAX Software Suite grant the ability to cut complex shapes and angles when used in conjunction with the AJet articulated cutting head.

Available on these machines:

OptiMAX 60X, OptiMAX 80X Series, OMAX 2626, OMAX 2652, OMAX 5555, OMAX 55100, OMAX 120X Series, OMAX 160X

Contact Sales

Features

- Powered by OMAX common table control

- Built-in water drip sensor

- Rapid height adjustment wheel on High Torque Rotary Axis

- Provides the ability for submerged cutting, leading to a cleaner and quieter process

- Robust standard ACME and metric threads allow customers to adapt custom work holding fixtures