What is ProtoMAX?

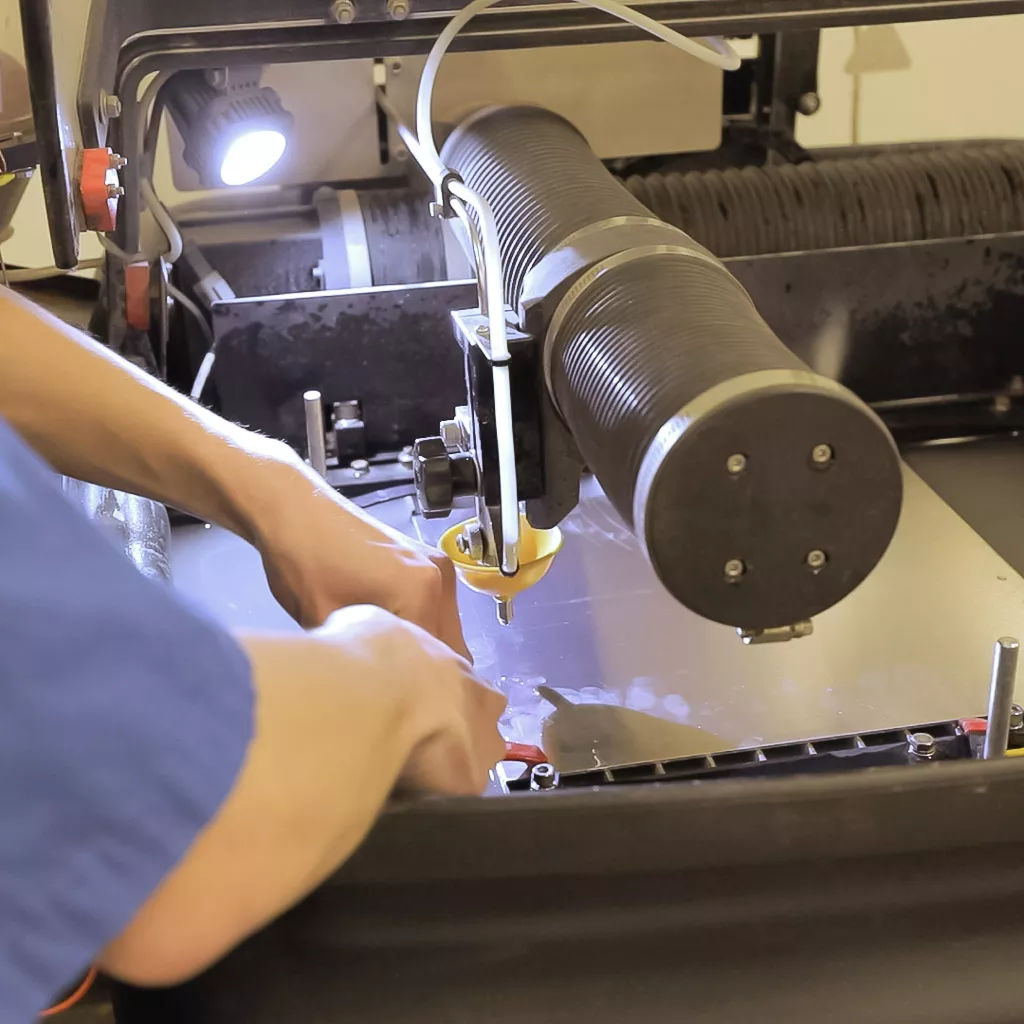

Designed and built alongside the revolutionary OMAX waterjets, The ProtoMAX is a compact, self-contained cutting system ideally suited for prototyping and low-volume cutting of almost any material approximately 1" thick. Bringing all the versatility benefits of large abrasive waterjet cutters together in a sleek and economic package, this machine is ideal for prototyping or as a complement to a larger machine shop.

CARACTERÍSTICAS PRINCIPAIS

Velocidade de deslocação até 2540 mm/min (100 pol/min)

com ±0,127 mm (±0,005") de precisão posicional linear

Sistema elétrico de 230-240 VCA monofásico, 30 A, 50/60 Hz

Kit de pré-instalação fácil de instalar para o ajudar a preparar-se para uma configuração rápida de 3-4 horas.

Dimensões: 1004 mm x 1435 mm x 1054 mm

(39,5" x 56,5 x 41,5)

Área de corte de 304 mm x 304 mm (12" x 12") para materiais com até 25 mm (1") de espessura

A tecnologia de bomba de transmissão direta de 3,7 kW (5 CV) com 2068 bar (30.000 PSI) gera a melhor potência da sua classe

Computador portátil com software profissional pré-instalado incluído.

ESPECIFICAÇÕES

| Zona de corte | 304 mm x 304 mm (12" x 12") |

| Espessura máx. do material | 25 mm (1,00") |

| Precisão posicional linear | ±0,127 mm (±0,005") |

| Repetibilidade | ±0,076 mm (±0,003") |

| Velocidade de deslocação | 2540 mm/min (100 pol/min) |

| Tipo de bomba | 3,7 kW (5 CV), transmissão direta |

| Pressão de corte | 2068 bar (30.000 psi) |

| Caudal de água de alta pressão | 0,2 mm (0,95 lpm) |

| Diâmetro interno do orifício | 0,008" (0,25 gpm) |

| Tubo de mistura | 57,15 mm (2,25") de comprimento; ±0,076 mm (0,030") de diâmetro interno |

| Sistema elétrico | 230-240 VCA, monofásico, 30 A, 50/60 Hz |

| Ambiente | Temperatura ambiente de 10-32 ºC (50-90 ºF) com 95% de humidade ou menos |

| Localização e fundação | Destinado a ser utilizado em espaços interiores; deverá de ser colocado numa superfície dura, nivelada, sólida, não porosa e resistente às chamas. Recomenda-se um pavimento de betão. |

| Pressão mínima da água de entrada | 3,1-5,9 bar (45-85 PSI) |

| Caudal mínimo | 2,8 l/min (0,75 GPM) |

| Temperatura necessária | 7,2-26,6 ºC (45-80 ºF) |

| Caudal | 0,11 kg (0,25 lbs) por minuto |

| Tamanho recomendado | 0,18 mm (80 mesh) |

| Capacidade da tremonha | 6,4 kg (14 lbs) |

| Bomba de 3,7 kW (5 CV) que gera 2068 BAR (30.000 PSI), a melhor potência de corte da sua classe |

| Espessura de corte DE até 25 mm (1") numa variedade de materiais |

| A nossa tecnologia comprovada de bombas de transmissão direta é eficiente e fiável |

| Software concebido para corte por jato de água abrasivo. Fácil de configurar e utilizar - o padrão de excelência do setor |

| Tamanho reduzido, perfeito para espaços pequenos, visto que passa por uma porta normal (podem ser necessárias algumas modificações) |

| Kit de pré-instalação para o ajudar a preparar-se para uma instalação rápida |

| O sistema e todos os componentes necessários para iniciar o processo de corte são fornecidos numa única embalagem |

| O mesmo é fornecido com ferramentas adicionais e peças de substituição para minimizar o tempo de inatividade |

| Vem com um computador portátil, pré-configurado com o software de controlo ProtoMAX |

| Instalação em 3-4 horas após a desembalagem |

| Eixo Z manual (cabeça de corte) |

| Unidade móvel: A bomba e o sistema estão montados em rodízios, o que torna a deslocação simples e fácil |

| Corte subaquático silencioso/limpo (aprox. 76 db) |

| Paragem automática da bomba durante o corte quando a tampa é levantada |

| Componentes de transmissão X e Y de precisão no interior de foles de proteção vedados |

| A manga ultra flexível de aço inoxidável protege a canalização HP |

| Luz industrial projetada na base de corte |

| Equipado com transdutor de alta pressão e válvula de segurança para otimizar a velocidade de corte e a segurança |

| Grampos para fixação de material |

| A bomba para durante as deslocações sem corte, o que poupa eletricidade |

| A utilização do bloco é minimizada com modelos de pressão e corte otimizados |

| O sistema está configurado com uma transmissão de frequência variável para um controlo do motor de elevado desempenho, que reduz o consumo de energia e a manutenção |

| Os recipientes de recolha dos blocos reduzem a frequência de limpeza dos depósitos e minimizam a libertação de partículas dos blocos |

| Painéis laterais amovíveis para facilitar o acesso para efeitos de manutenção |

| Necessidade mínima de manutenção |

| Base de corte amovível - fornecida com 12 ripas |

| Conjunto da bomba devolvido à OMAX para reparação ou reprocessamento |

| Manuais online fáceis de seguir com instruções de funcionamento, manutenção e resolução de problemas |

Laptop Tray

Start up, shut down and cutting preparation are easier when your controlling laptop is in close reach. Mounts directly to the side of your catcher tank and includes a bead chain for quick access of your standoff gauge.

Cutting Bed Kit

This option is great for cutting thin metals, cloth, gaskets, plastics which will drape between the slats and also glass, mirror and other materials which can fall through slats after cutting.

Hose Kit

Specifically engineered for the attachment to the water manifold, the hose kit is rated for continuous pressure without leaks or bursts and shipped with handy bracket to hang the spray nozzle on.

Spares and Consumables Kit

Your standard replenishment parts inventory with all the items you need for sustained operation. The kit includes extra slats, mixing tubes, orifices, garnet feed line, mixing tube retainer nut, nozzle body o-ring, water filter, splash guard and last chance filters.

Spares and Accessories Kit

Our most popular kit. This provides all the replenishment parts you’ll need over an extended time including extra slats, mixing tubes, orifices, garnet feed line, mixing tube retainer nut, nozzle body o-ring, water filter, splash guard and last chance filters plus the drain water filter tank and water spray nozzle.

Screen Drain Filter

Drain tank water faster. The suction screen is a self-installed alternative to the standard foam drain filter included with the ProtoMAX. This design offers maximum drain flow rate and requires minimal cleaning.

Tank Drain Kit

Although most regions allow water from your catcher tank to flow to drain, certain locations and institutions may require additional filtration. This accessories contains a submersible “sump” pump that takes the filtered water direct to drain.

COMPARAÇÃO DE PACOTES

Atualizar pacote

Todos os extras para tornar o corte mais eficiente

INCLUI

- Mesa de corte de jato de água abrasivo ProtoMAX

- Bomba de transmissão direta ProtoMAX de 30,000psi e 5 cv

- Montagem do bocal

- Balde de 55lb com abrasivo em bloco

PORTÁTIL E SOFTWARE

- Portátil

- IntelliMAX Proto Software

- Utilizadores de software ilimitados

- Atualizações de software grátis para toda a vida

- 1 ano de garantia

ACESSÓRIOS

- Kit de peças sobressalentes do sistema

- Depósito do filtro de água de drenagem

- Kit de pulverização de água

Pacote de potência

Pacote de atualização mais bloco extra para corte contínuo e potente por jato de água

INCLUI

- Mesa de corte de jato de água abrasivo ProtoMAX

- Bomba de transmissão direta ProtoMAX de 30,000psi e 5 cv

- Montagem do bocal

- Balde de 55lb com abrasivo em bloco

PORTÁTIL E SOFTWARE

- Portátil

- IntelliMAX Proto Software

- Utilizadores de software ilimitados

- Atualizações de software grátis para toda a vida

- 1 ano de garantia

ACESSÓRIOS

- Kit de peças sobressalentes do sistema

- Depósito do filtro de água de drenagem

- Kit de pulverização de água

- 6 baldes de abrasivo em bloco, balde de 55lb

Pacote Standard

Consumíveis adicionais para manter a sua operação a funcionar sem problemas

INCLUI

- Mesa de corte de jato de água abrasivo ProtoMAX

- Bomba de transmissão direta ProtoMAX de 30,000psi e 5 cv

- Montagem do bocal

- Balde de 55lb com abrasivo em bloco

PORTÁTIL E SOFTWARE

- Portátil

- IntelliMAX Proto Software

- Utilizadores de software ilimitados

- Atualizações de software grátis para toda a vida

- 1 ano de garantia

SOFTWARE DE CORTE LÍDER NO SETOR

O nosso software IntelliMAX Proto, concebido especificamente para jato de água, possui características que garantem a precisão e otimizam o tempo de corte. O nosso software é tão benéfico para um corte eficiente e preciso que fornecemos um número ilimitado de utilizadores individuais licenciados para a sua organização.

Saber mais Descarregar software

CRIE DESENHOS PESSOAIS A PARTIR DO ZERO

Concebido exclusivamente para jato de água, o nosso software IntelliMAX Proto inclui as funcionalidades típicas da maioria dos pacotes CAD. Além disso, também inclui ferramentas específicas de jato de água, como qualidade de corte e entrada/saída, que ajudam a criar a peça certa à primeira.

Ver tutorial Descarregar software

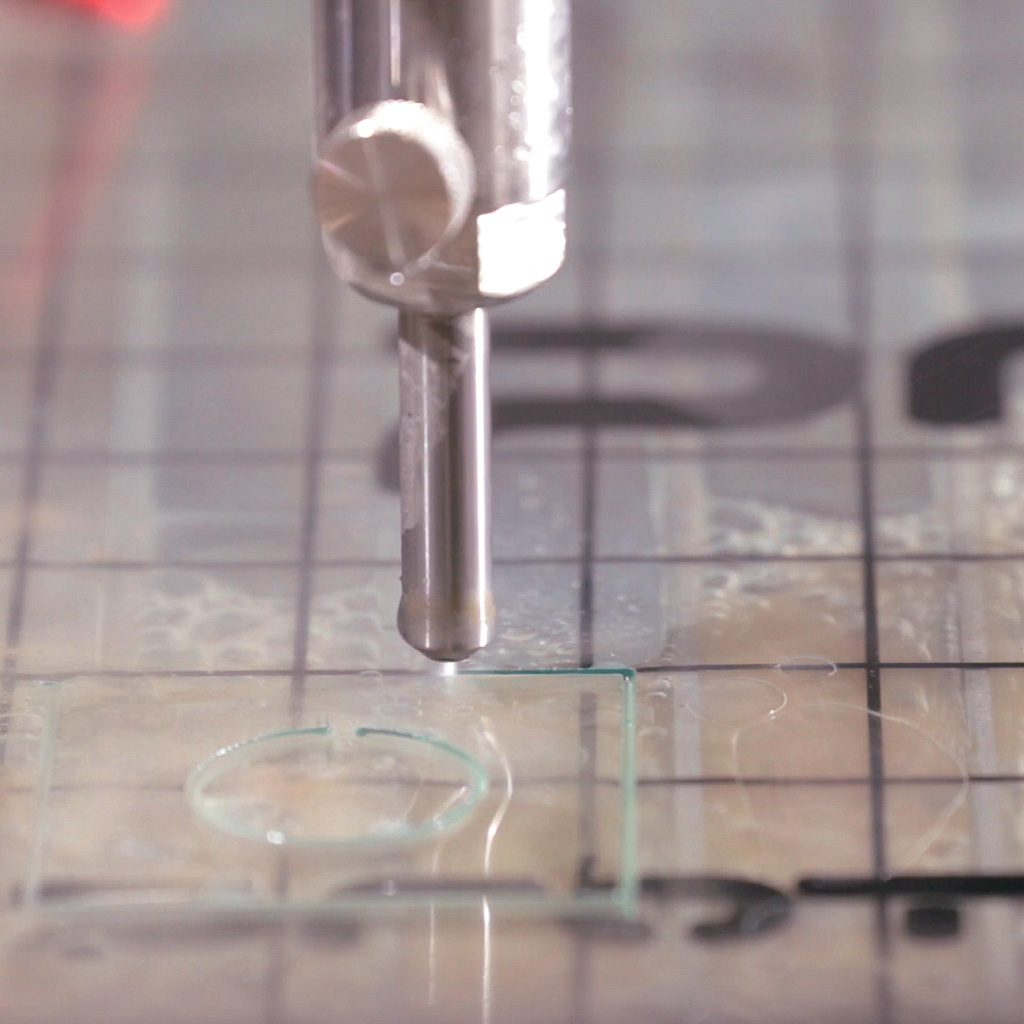

Erosion. Pressurized water is directed into a fine stream that accelerates garnet particles into and subsequently through the material you are trying to cut.

The ProtoMAX system requires a 240VAC / 30A power source and access to water and a drain. The power requirement is similar to a household clothing dryer and is required to drive the 5 horsepower pump. Check out our Utility Requirements document for more information. Water temperature and quality can impact how well the ProtoMAX runs. While we have successfully tested the ProtoMAX over a wide range of temperatures and water conditions, we offer the following recommendations for optimal operation:

- Temperature: 45 - 80°F

- pH Level: 6.5 - 8.5

- Total Dissolved Solids < 250 ppm

- Calcium < 17ppm

- Magnesium < 6 ppm

- Iron < 0.3 ppm

- Manganese < 0.05 ppm

- Chloride < 100 ppm

- Sulfate < 200 ppm

- Silica < 10 ppm

The ProtoMAX can cut through nearly any material including all those listed below and more. To get a better look at materials any OMAX waterjet can cut click here.

| Material |

|---|

| Aluminum |

| Stainless Steel |

| Mild Steel |

| Granite |

| Marble White |

| Acrylic |

| Glass |

| Carbon Fiber |

| Foam |

The ProtoMAX is the fastest cutting waterjet of its size. It has a 5 hp pump and operates at a pressure of 30,000 PSI. Industrial waterjets operate at pressures between 45,000 and 90,000 PSI so while you're not going to cut at industrial speeds, you will still cut fast.

Below is a table that shows some basic materials, thicknesses and linear cutting speed. All cuts were performed at Quality 3 (Q3). Edge quality is defined within a range of Q1 - Q5 with Q5 being the best, i.e. with very little serration or roughness. You can choose quality of cut within the ProtoMAX control software which optimizes the speed of cut by selecting the fastest path for quality chosen.

| Linear Speed * | ||

|---|---|---|

| Material | Thickness | Inches Per Minute (IPM) |

| Aluminum 6061 | .125" | 9.4 |

| Aluminum 6061 | .250" | 4.55 |

| Aluminum 6061 | .500" | 2.13 |

| Stainless Steel 304 | .060" | 7.93 |

| Stainless Steel 304 | .120" | 3.95 |

| Mild Steel | .188" | 2.46 |

| Mild Steel | .250" | 1.82 |

| Granite Absolute Black | .375" | 1.48 |

| Granite Snoqualmie | .375" | 2.28 |

| Marble White | .375" | 2.9 |

| Acrylic Clear | .120" | 18.41 |

| Glass Sheet | .250" | 4.52" |

| Carbon Fiber | .040" | 45.93 (Q5) |

| Carbon Fiber | .120" | 27.44 |

* Listed here are linear cutting speeds, as one could expect to achieve when cutting in straight line. When cutting real-world geometry with curves and corners, the cutting is significantly slower, due to the need to slow down the cutting for the jet behaviors. Parts with lots of corners will be significantly slower than straight line cuts or shallow curves. All of this calculation is handled for you automatically by ProtoMAX MAKE's built in cutting models.

Quality 3 is based on cutting scale of Q1 to Q5. Q3 has a very good edge finish at a reasonable cut speed. Cutting faster, (Q1) will result in rougher edge finish and additional taper. Cutting slower, (Q5) will result in a very smooth cutting surface with no striations and minimal taper.

The ProtoMAX uses 0.42 gallons per minute while cutting, which is a combination of high pressure and cooling water.

It depends. Water and garnet, a naturally occurring mineral, are inert. The water draining from the catcher tank will contain abrasive and a small amount of the material that is cut and that may influence what you can pour down the drain. Check your local wastewater regulations to learn what you can and cannot dispose of down the drain.

12 inches X 12 inches square. For more specifications, download product specs.

We don't recommend recycling garnet for use in your ProtoMAX system as your cutting performance may suffer. Used garnet can be disposed of in landfills or repurposed by concrete manufacturers. To learn more read - When it’s Time to Remove Solids.

We've built the ProtoMAX to require minimal maintenance, which includes:

- Flushing the nozzle (water without garnet) after each use

- Changing the pump oil every year or 250 hours, whichever occurs first

- Removing the spent garnet periodically depending on usage

We are designing the system to be compliant with UL requirements.

The ProtoMAX lid is designed to stop all cutting when open and the On / Off switch is ergonomically located on the side of the machine. ProtoMAX may emit minimal water vapor from the cutting process.

In our intgernal testing, the machine operated at 76db when cutting under water.

The ProtoMAX system includes:

- Unit enclosure

- XY motion system, cutting platform, and a catcher tank

- Nozzle and mixing tube

- 5 hp pump (operating at 30,000 PSI)

- All electrical and plumbing

- Laptop configured with Intelli-MAX software

- 55 lbs. of garnet

Everything you need to begin operation after install.

ProtoMAX has an online marketplace where you are able to purchase garnet, consumables and ProtoMAX accessories.

The ProtoMAX system weighs about 300 lbs for the table and 200 lbs for the high pressure pump, plus about 100 lbs for packaging and accessories. The unit is shipped on one pallet. You may also choose from a variety of additional accessories that would be shipped on a separate pallet. We will ship via truck with a lift gate for ease of off load.

The crated ProtoMAX crated weight is about 600 pounds and we will choose a freight company that has lift system to lower the unit to the ground. The product is shipped on a 49" X 49" pallet that can be moved close to your installation location or you can offload the product and wheel it to your location. We recommend at least two people to help with the offloading, unpacking and installation procedure.

Yes. The ProtoMAX table and pump are equipped with casters to make moving easier. Keep in mind that moving the unit will require duplicating many of the installation procedures in the new location.

The ProtoMAX is available worldwide.

A ProtoMAX measures 41.5 inches deep X 39.5 inches wide. It measures 69 inches tall with the clam shell open. OMAX recommends 16 inches between the machine and your wall for utility connections. The box the ProtoMAX arrives in is 49 inches deep by 49 inches wide and 61 inches tall.

Based on the feedback from our beta-testers, it's pretty easy. Our testers ranged in experience and age and most found drawing, importing and pathing to be uncomplicated. We will make the software available soon and encourage you to try it and decide for yourself.

The Intelli-MAX software makes it easy to do both. Layout is our CAD software that can be used to draw or import files. Below is a partial list of file extensions that can be imported into LAYOUT (and in some instances use Intelli-TRACE) to create tool paths:

| File Extensions |

|---|

| .dwg |

| .dxf |

| .ord |

| .svg |

| .ai |

And many more.

The ProtoMAX is designed with that in mind. As long as your computer meets the minimum system requirements (essentially Windows 10 64 bit), then it should work. Setup is just running the installer, and answering a few questions. The main purpose of doing this is to have a computer more powerful than the very basic one supplied, which can be nice for those who wish for a snappier experience.

Yes, although some future software products, add-ons, and the like may be at some cost.