Intellimax Software by OMAX

Running on Windows 10, the OMAX IntelliMAX Software Suite delivers extraordinary power and performance while remaining intuitive and easy to use. From creating a drawing to importing part files, IntelliMAX easily takes your design and prepares it for machining. Powerful cutting enhancements complete the process, quickly converting your design into reality with efficiency and precision.

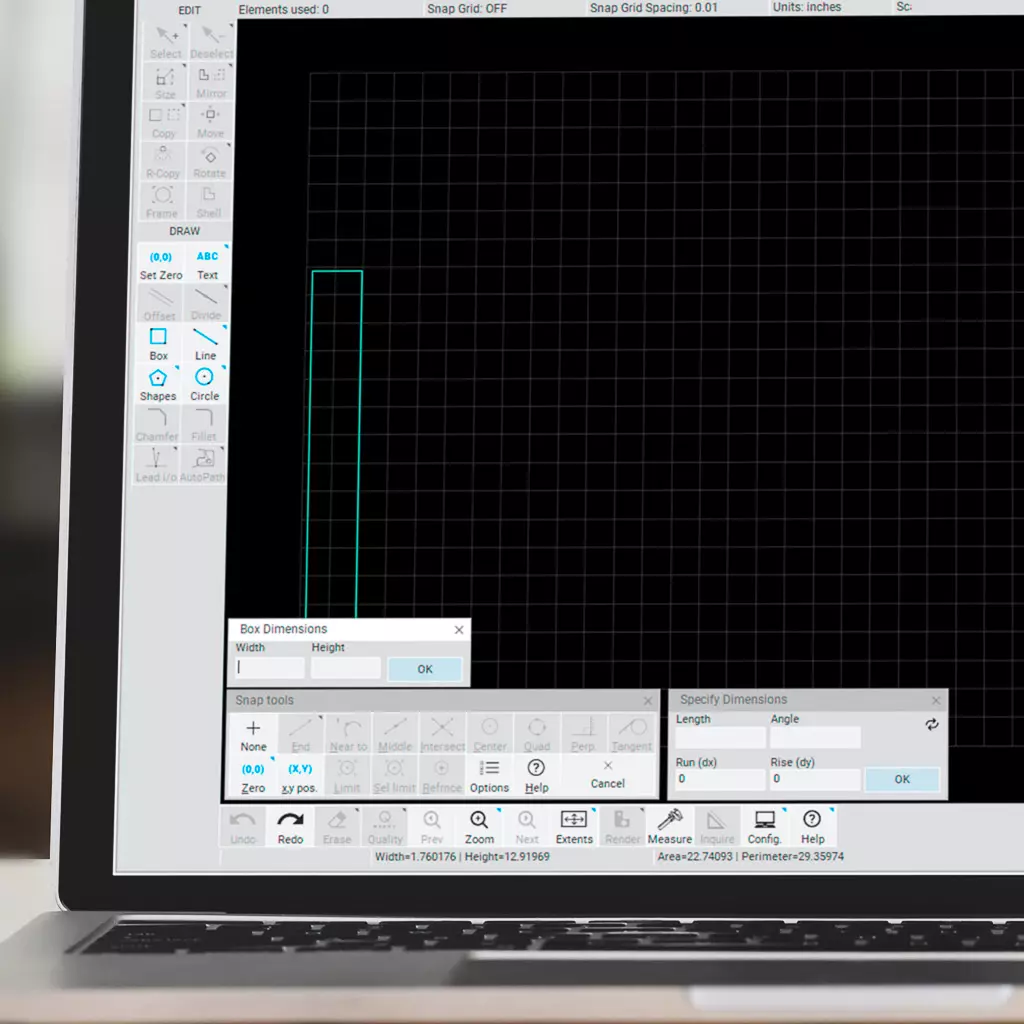

LAYOUT

LAYOUT is our innovative CAD software that creates tool paths for your OMAX produced abrasive waterjet system. LAYOUT includes all the basic commands you'd expect to find in a CAD package, as well as a whole suite of tools specific to abrasive waterjet and waterjet machining, including cut quality specification, tool path fonts, gear and rack generation, and a lot more.

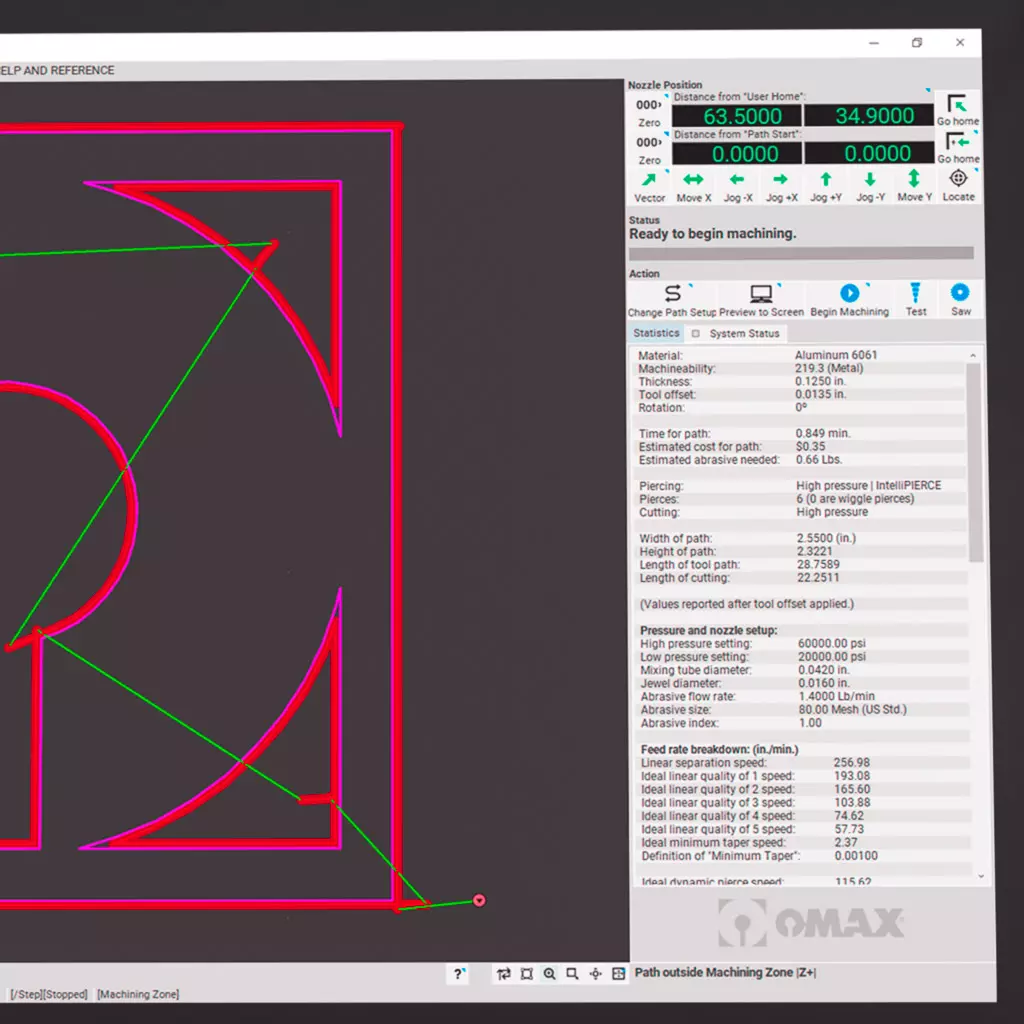

MAKE

Designed from the ground up specifically for abrasive waterjet control, MAKE controls your OMAX or MAXIEM JetMachining Center by sending precise motor control commands to move the nozzle along your tool path, while simultaneously controlling the flow of abrasive and high-pressure water. By applying advanced internal cutting models, and using built-in compensations for speed, acceleration, and backlash, MAKE provides exceptional results in rapid high-precision abrasive waterjet machining. Advanced corner and piercing optimizations are also automatically applied, for even greater cutting speed and precision.

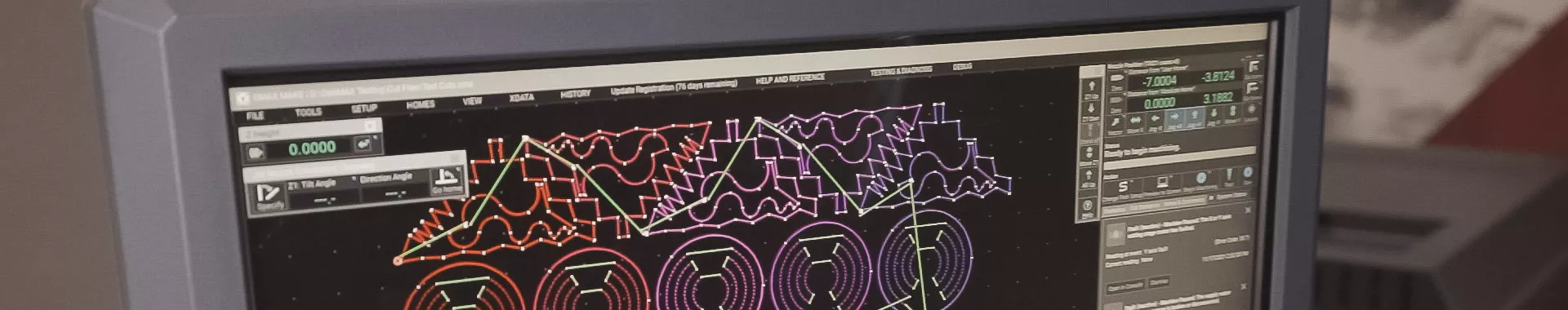

IntelliCAM

IntelliCAM is a highly advanced computer-aided manufacturing (CAM) software program with two tools in one that can generate either 2D or 3D tool paths from 3D models. Simply import a 3D file from one of the many supported file types such as CATIA, SolidWorks, 3D DXF, or DWG, and others, and the 3D object appears in an interactive window. Generating a 2D profile from any face or slice of the 3D shape is just a click away. The other side of IntelliCAM shows that 3D pathing is just as easy. With the AutoPath function, the program automatically creates the waterjet-reasonable tool path and applies the required attributes for 3D cutting before exporting directly to IntelliMAX MAKE.

Supported File Formats

The OMAX IntelliMAX Premium Software Suite features the broadest file support in abrasive waterjet software. From standard 2D DXF files to advanced 3D shapes, IntelliMAX can import from all major CAD/CAM and artistic drawing programs, allowing you to use your existing workflow.