Media Center

MEDIA CENTER

Tips and Tricks

IntelliMAX-Think Smarter

Integrated software system is best for a soft cutting tool Read

Titanium and Abrasive Waterjet: The Perfect Match

Nose-to-tail aircraft interiors and exteriors, spacecraft, satellites, and defense systems rely on titanium as the metal of choice to meet high performance expectations. Titanium offers high strength-to-weight ratio, excellent corrosion resistance and the ability to withstand extreme temperature for the high stakes manufacture of existing and new aerospace products. Read

Waterjet Cutting Saves Time and Money for Near Net Shape Production

For decades, parts makers have used near net shape production as an initial step to form parts and components very close to their final shapes. Near net shape has become more important with the increased use of expensive, exotic materials and the demand for leaner, more cost-efficient production. Abrasive waterjet is an ideal tool for the expanding industries that benefit from near net shape production. Read

Press Releases

Hypertherm Assoc. selects Aaron Brandt as successor to CEO Evan Smith

Brandt will become the third CEO since Hypertherm Associates’ founding in 1968, following the strong leadership legacy of co-founder Dick Couch, CEO from 1968-2014, and Evan Smith, who succeeded Couch. Read

Hypertherm Associates to close down legal entity in Russia

HANOVER, N.H.—Nov. 1, 2022—Hypertherm Associates, a U.S.-based manufacturer of industrial cutting products and software, today announced plans to formally close its legal entity in Russia. Read

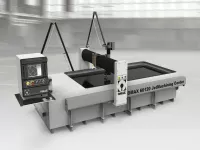

Hypertherm’s OMAX and Robotmaster head to Chicago for IMTS 2022

Hypertherm, a U.S. based manufacturer of industrial cutting systems and software is preparing to exhibit at IMTS 2022. This year’s International Manufacturing Technology Show, the largest manufacturing technology trade show in North America, takes place September 12 to 17, at Chicago’s McCormick Place Convention Center. Read

News Articles

Jetting to success

A New York-based shop implements waterjet technology and gains value Read

Digging deep

Fabricating projects in the engineering program’s shop helps prepare students for not only continuing their education after high school and, more importantly, for life. Kamal notes that students who are accepted into his program spend more than 1,000 hours studying engineering, including a lot of fabrication in class and as part of the after-school robotics club. Read

Waterjet Case Study: The complete package

Montreal packaging solutions manufacturer continuously invests in automation to keep pace with growth and keep its R&D on point Read

Videos

The Importance of Water in Abrasive Waterjet Cutting

Not all water is the same, and when it is used in a machine tool, those differences can have unforeseen effects. OMAX Filtration Systems Specialist John Frosheiser discusses the potential challenges and solutions regarding water and your OMAX waterjet system. Read

4 Waterjets, 6 Materials, and 9 Parts, All in under 10 minutes

Watch our application specialist Ivan Kondeykin operate all four abrasive waterjet machines in the OMAX Demo Lab simultaneously. From thick metals to thin carbon fiber, taper-free vertical cuts to 5-axis high angle cuts, and advanced rotary axis parts to high precision parts, Ivan does it all. Read

Cutting a Scuba Tank with the Rotary Axis

Thick material, a cylindrical part, and complex cut geometry, this has it all. Join Ivan Kondeykin in the OMAX applications lab and see how the OMAX Rotary Axis and IntelliMAX software makes this project easy. Read